Pleo’s Innovation

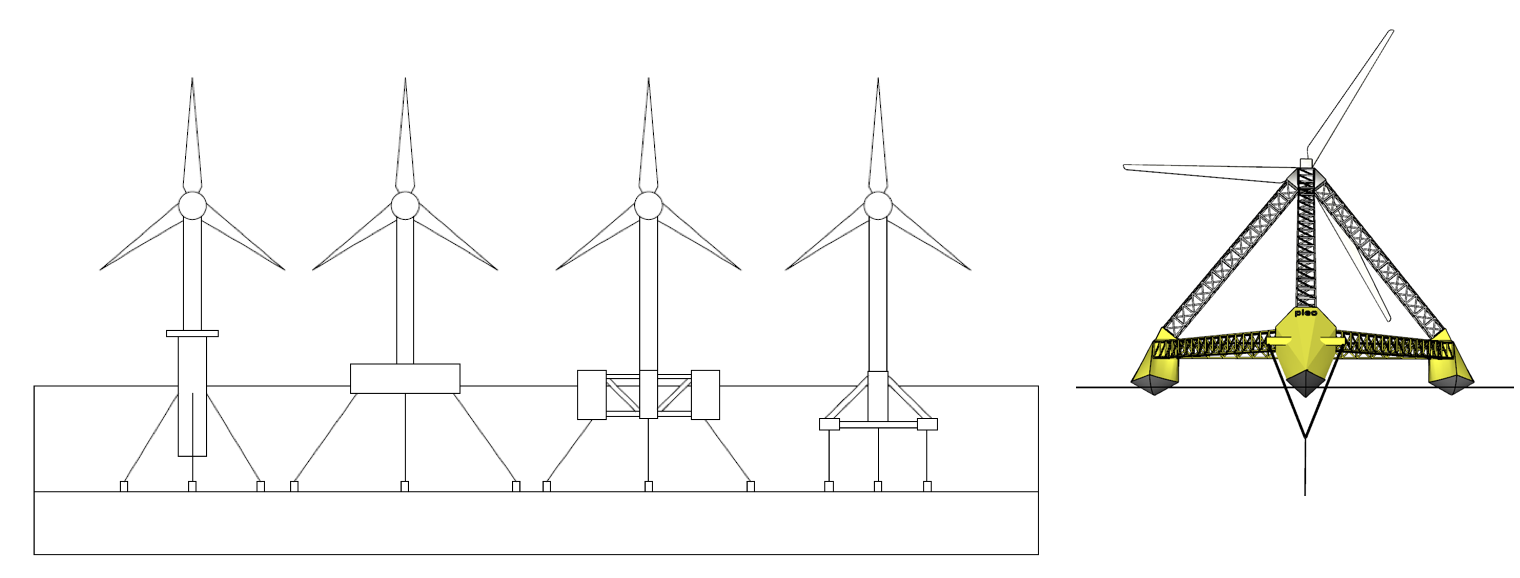

The offshore wind industry is constantly evolving, but to fully unlock the potential of floating wind farms, innovative solutions are crucial. Pleo’s design integrates seven key areas of innovation, all aimed at delivering a more cost-effective platform to support large wind turbines.

Concept Innovation

Pleo diverges from traditional offshore oil and gas structure design. While those designs are proven, they are less cost-effective for offshore wind energy. Pleo is a new, more efficient approach.

Material Innovation

Instead of conventional steel, Pleo is constructed using composite materials that are corrosion-resistant, lightweight, strong, and durable. Composites require minimal maintenance and have good fatigue properties, enhancing service life. Using advanced pultrusion and pull-winding techniques, Pleo’s components can be mass-produced to a high standard.

Composite materials, such as those used in boat construction, offer the perfect balance of strength, low weight, and cost-efficiency.

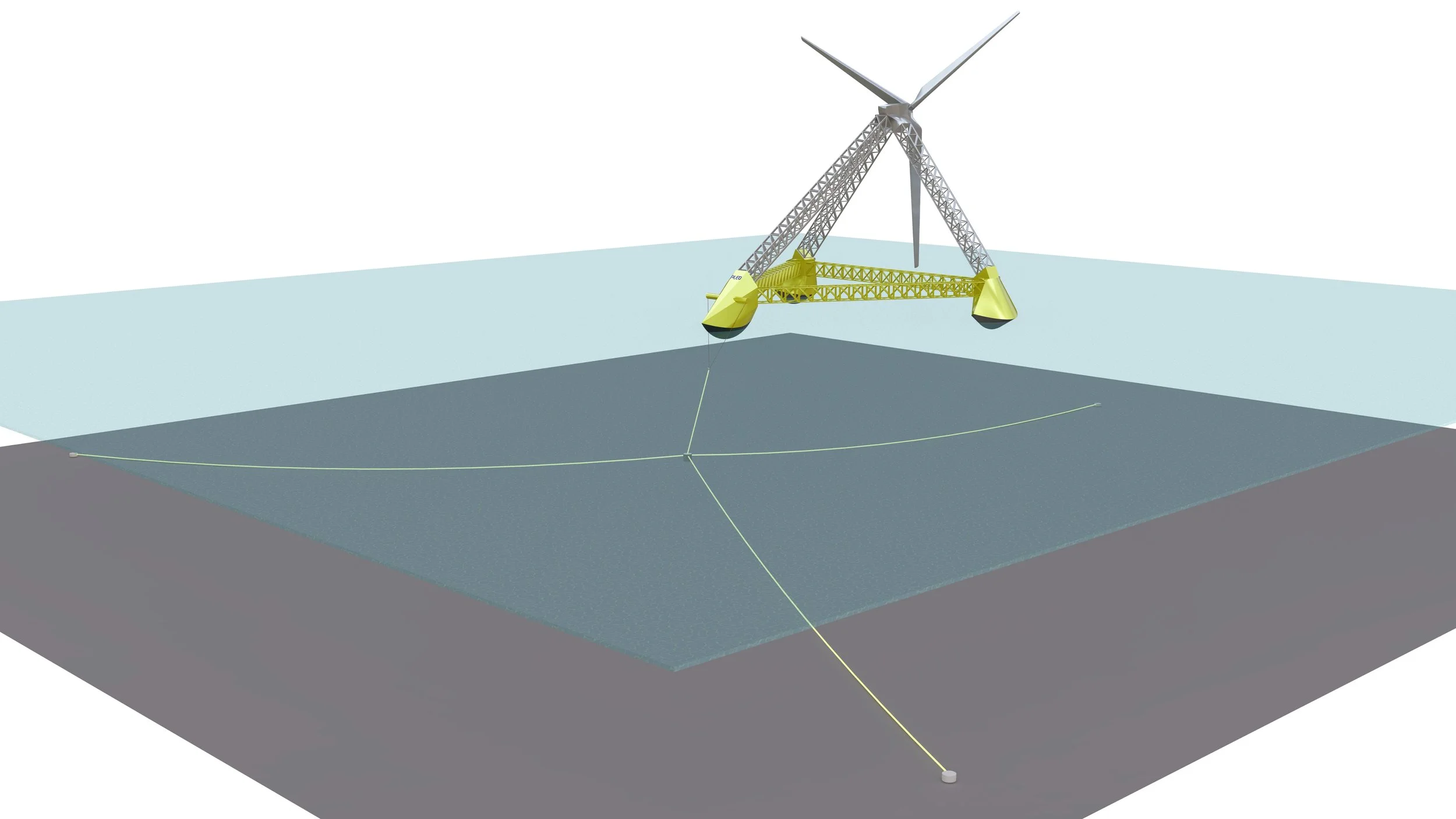

Mooring Innovation

Pleo features a low-cost mooring design capable of handling extreme sea conditions at both deep and shallow water locations, offering both versatility and survivability.

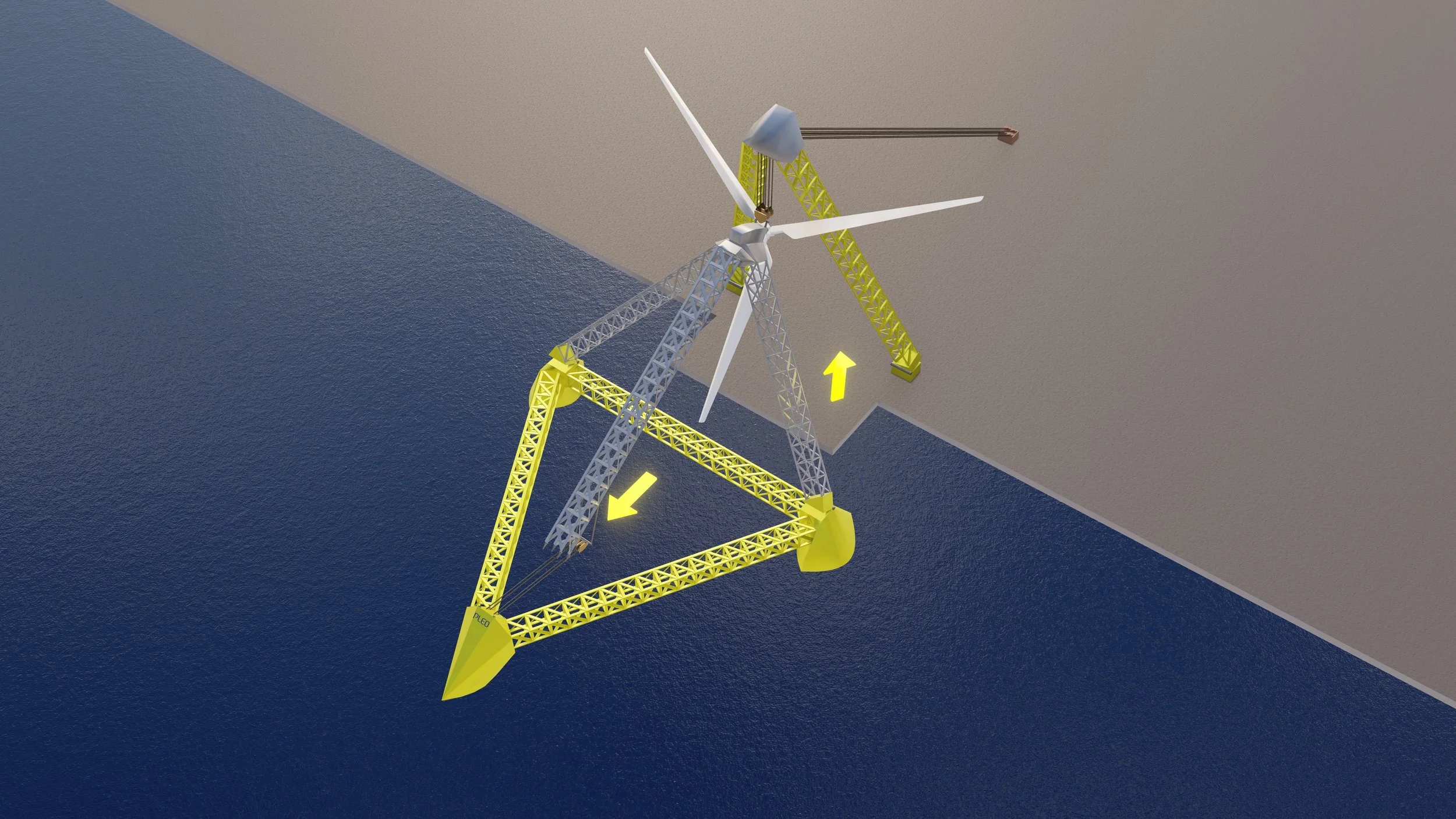

It uses a weathervaning mooring system, a common setup in the offshore oil industry for floating production. As is common in the oil industry, thrusters are installed at the vessel's aft end to ensure directional stability and to allow the electrical connection to be unwound as needed.

Geometry Innovation

Pleo's hydrodynamic hull is engineered to minimize superstructure loads, which reduces overall weight and cost. Its adaptable design supports various turbine sizes and configurations, including both single and multi-rotor setups.

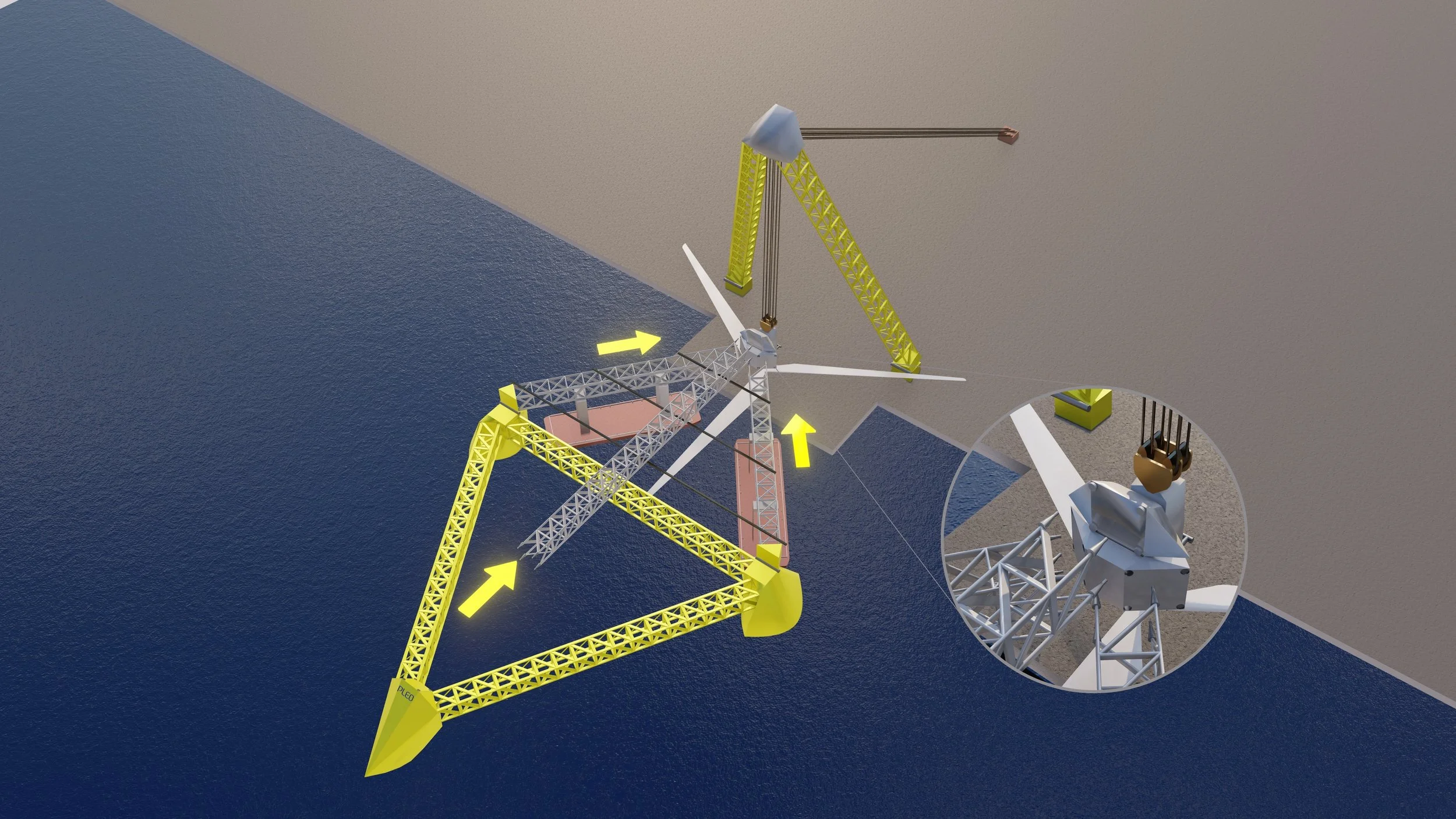

Installation and Maintenance

The Pleo mooring system can be pre-installed on the seabed, allowing Pleo to be quickly attached when weather conditions are suitable, using standard offshore oil industry techniques. This connection can be easily reversed for major maintenance tasks.

With a draft of less than 6m for a 15MW design, Pleo does not need a deep-water harbour —only a sheltered location. The streamlined hull also enables efficient towing by small tugs, reducing both costs and emissions during transport.

Environmental Impact

Pleo’s lightweight composite structure is designed for low carbon intensity. Additionally, Pleo aligns with innovative recycling techniques being developed for wind turbine blades and other composite structures.

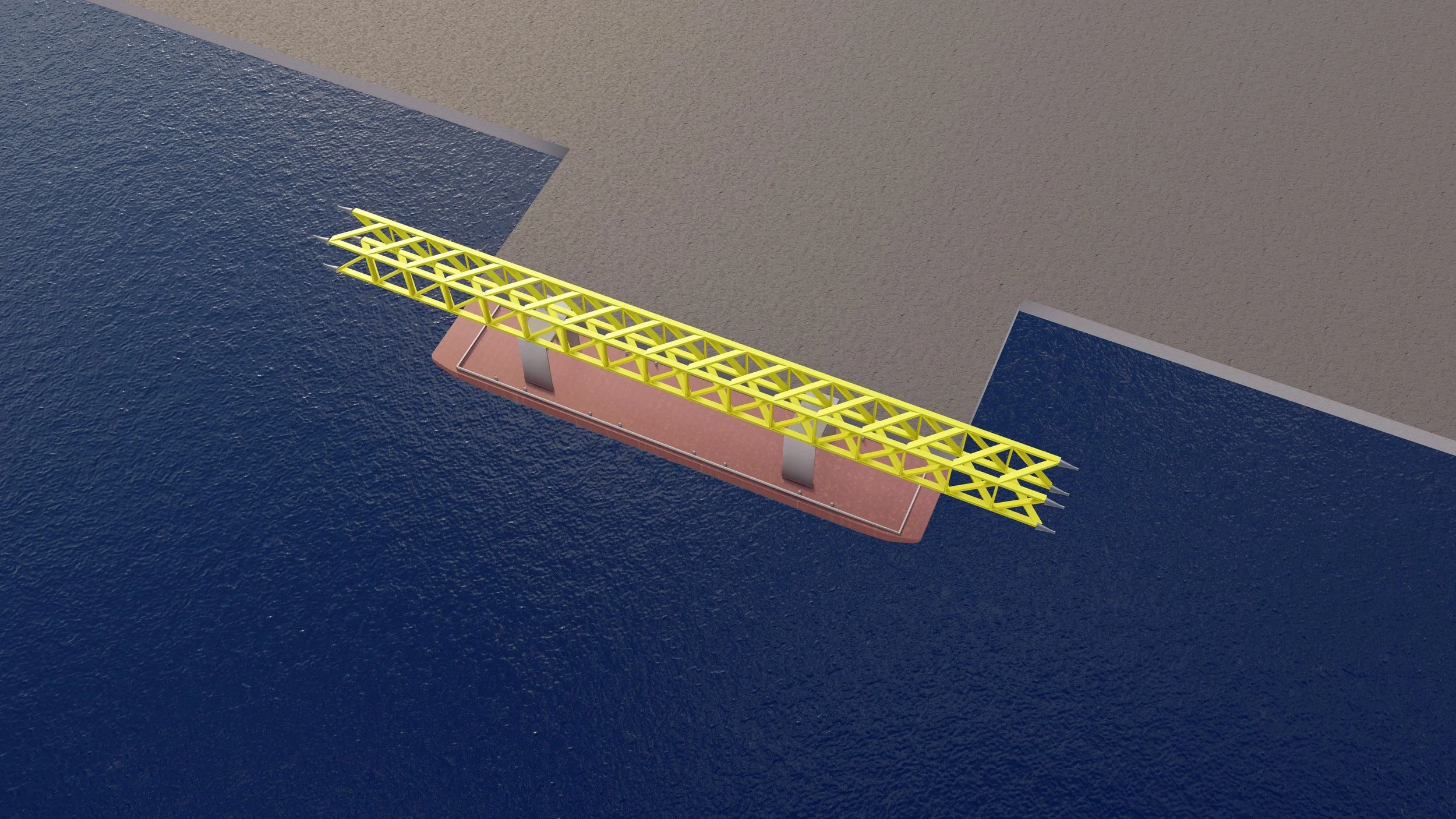

Manufacturing and Mass Production

Pleo is designed for straightforward, low-cost manufacturing. The floats are moulded in a similar way to mass-produced GRP (glass-reinforced plastic) leisure boats, and the trusses are crafted from GRP pultruded sections, which feature precise tolerances for easy, pipe-like connections.

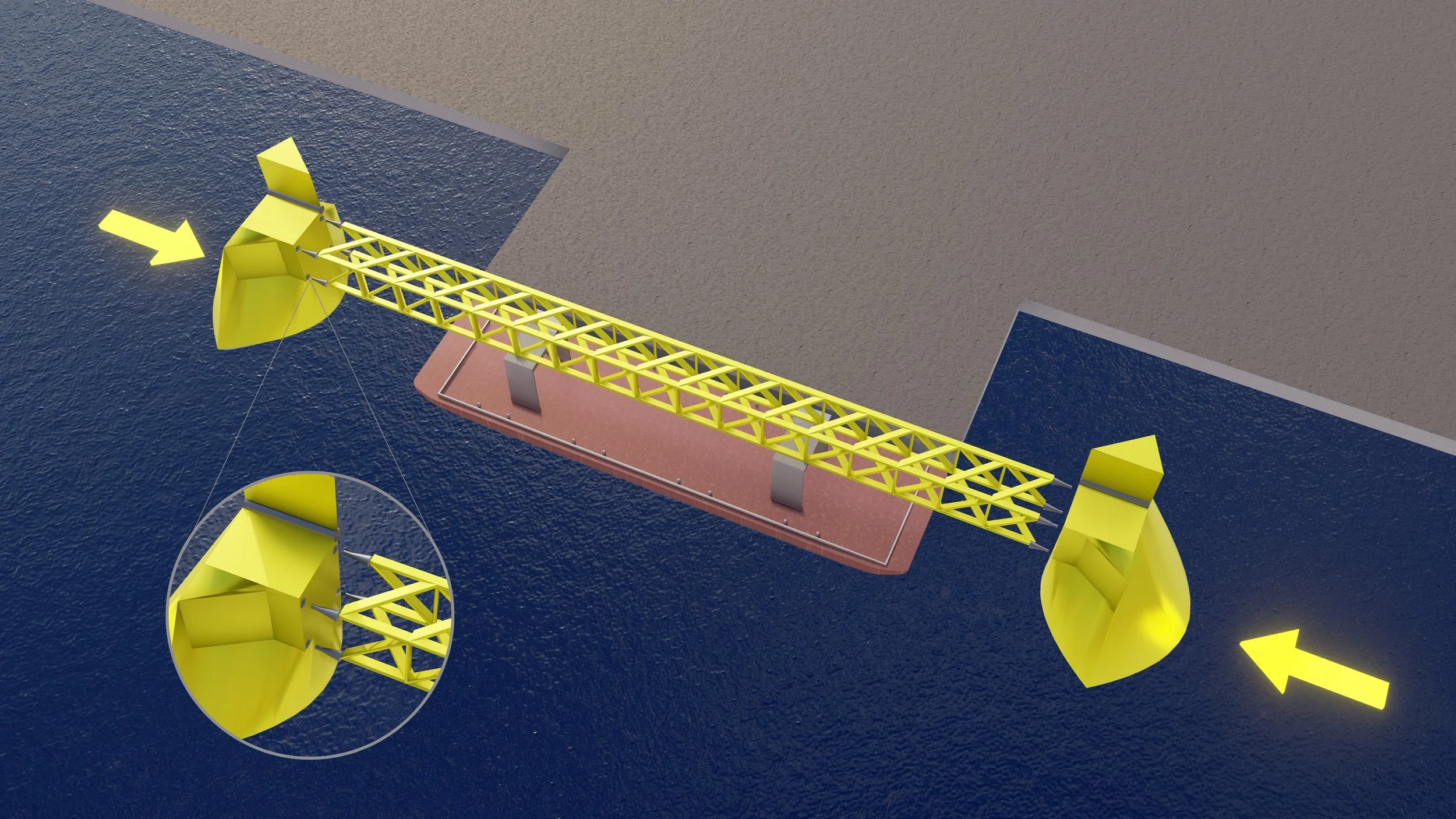

Tapered steel bolts connect the trusses and floats, allowing assembly without the need for exact alignment. Final assembly is simplified, as components can be floated together in a sheltered area. Pleo’s folding design eliminates the need for work at height and no dockyard is necessary.

FAQs

-

Pleo’s platform stands out due to its innovative approach to hydrodynamics, materials, and manufacturing. Instead of steel, Pleo uses composite materials which are lightweight, corrosion-resistant and durable. Modular design allows for mass production at a lower cost, making offshore wind energy more accessible and scalable.

-

Pleo’s innovative design minimizes costs in four main ways:

Using composite materials that reduce weight and maintenance needs;

Streamlining manufacturing with proven pultrusion and pull-winding techniques;

Designing for local production to lower transportation costs and decouple from traditional supply chains; and

Implementing a foldable structure that simplifies turbine final assembly and maintenance.

-

Pleo is designed with sustainability in mind. The use of lightweight composite materials lowers the platform’s carbon footprint. Additionally, the design reduces emissions during transportation and installation by enabling towing with small tugs. We also recognise innovative recycling techniques are being developed for wind turbine blades and composites, further reducing environmental impact.

-

Yes, the Pleo platform is highly adaptable. It can accommodate various turbine sizes and configurations, including single and multi-rotor setups, making it suitable for a wide range of offshore wind farm projects.

-

Pleo’s shallow draught mean it can be deployed from a wide range of construction sites without the need for deepwater harbours. Pleo’s innovative mooring system make it suitable for deployment in extreme seastates in both deep and shallow waters. This versatility allows for a wide range of installation sites.

-

Pleo platforms are designed for long-term durability. The composite materials used in the construction are highly resistant to corrosion and fatigue, which minimizes maintenance and extends the operational lifespan of the platform.

-

Pleo’s platform is designed to fold flat during turbine and blade installation, significantly reducing the need for high-reach cranes. This innovation not only simplifies the installation process but also reduces associated costs.

-

A key area of innovation for Pleo is use of composite materials and the use of composites at this scale is unprecedented. Traditional construction materials like steel and concrete have been developed over centuries. The rate of learning for composites is still very steep with increasing adoption in many areas of industry including automotive, aerospace, boat building and bridge design.

-

By focusing on cost-effective design, efficient manufacturing, and local production, Pleo reduces the financial and logistical barriers to offshore wind projects. This makes it easier to scale up offshore wind farms, helping to accelerate the global transition to renewable energy.